Techtimia Engineering Pte. Ltd was established in 2015 in Singapore by Irwin Wilson. The company has been engaged in providing a range of prototype-making services.

Under the stewardship of Mr. Wilson, who has more than ten years of experience in this sector, Techtimia Engineering Pte. Ltd has been able to overcome all odds and now has built a reputation within the CNC machining services industry among its clientele.

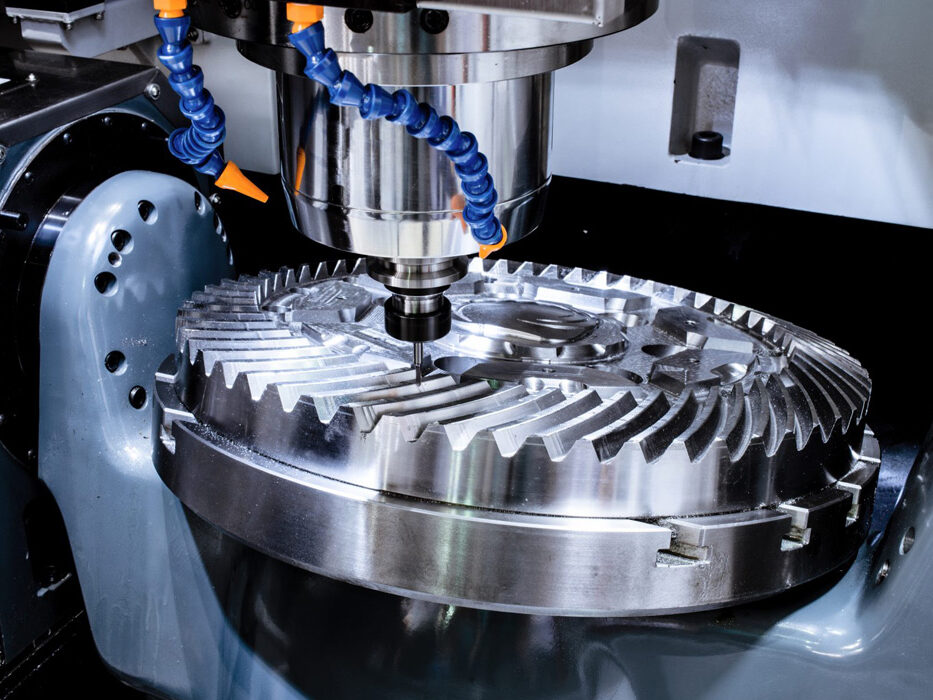

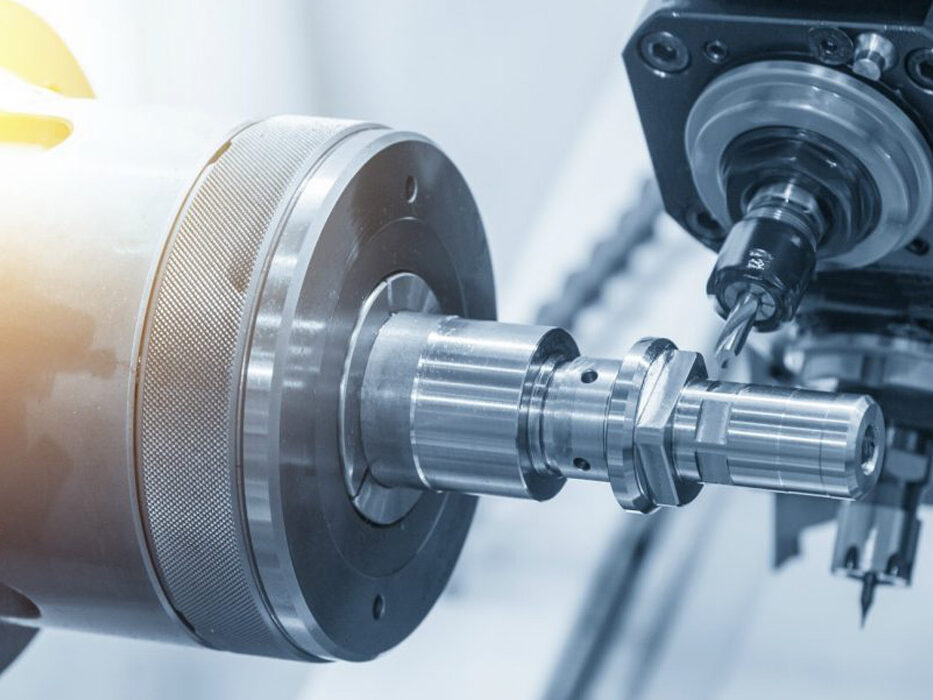

The company has expanded its machining services in Singapore, which include making prototypes, CNC Machining, Injection Molding, Die Casting, and other value-added services.

Under Irwin Wilson’s leadership, the company strategically expanded its business network in 2018.